We offer are manufactured under strict quality supervision. These jack find usage in critical application across Hydro Power Plants, Thermal Power Plants, Defence, Aerospace-Industries, Railways, etc. These jack can be custom configured and supplied with certification as required by customers. All jacks provided by us employ international quality parts & components, that are offer long trouble free life.

Salient Feature :

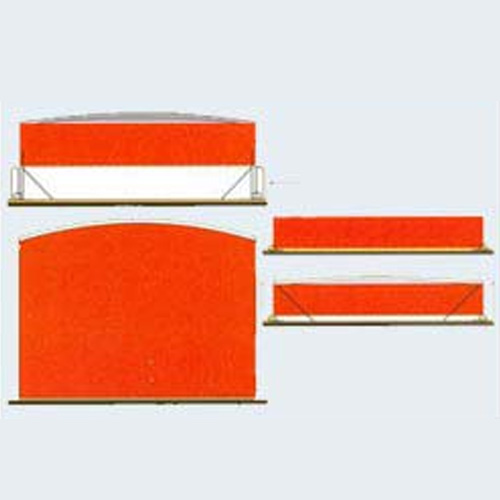

Bell Hydromatics Tank Jacking Equipments are used for :

Construction, Dismantling, Repairs, Replacement, Maintenance of Tanks, Changing of Tank foundations, Tank base plates

Advantages :

Technical Specifications :

| MODEL | BH-12-100-SA | BH-18-100-DA | BH-25-100-DA |

| Capacity | 12 MT | 18 MT | 25 MT |

| Hydro-Testing at | 18 MT | 27 MT | 37.5 MT |

| Recommended distance between jacks | Max 3.0 mt | Max 3.0 mt | Max 3.0 mt |

| Suitable for shell/plate width | Min 1.4 mt and Max 3 mt | Min 1.4 mt and Max 3 mt | Min 1.4 mt and Max 3 mt |

| Plate thickness | 6-40 mm | 8 mm and above | 8 mm and above |

| Stroke of Jack | 100 mm/stroke | 100 mm/stroke | 100 mm/stroke |

| Hydraulic working Pressure | 106 bar | 115 bar | 160 bar |

| Test Pressure Hydraulic | 160 bar | 172 bar | 240 bar |

| 10 HP Powerpack | 34 jacks | 24 Jacks | 24 Jacks |

| 15 HP Powerpack | 50 Jacks | 36 Jacks | 36 Jacks |

| 20 HP Powerpack | 65 Jacks | 50 Jacks | 50 Jacks |

| 30 HP Powerpack | 80 Jacks | 60 Jacks | 60 Jacks |

| 50 HP Powerpack | 120 Jacks | 90 Jacks | 90 Jacks |

Tank Construction Methodology :

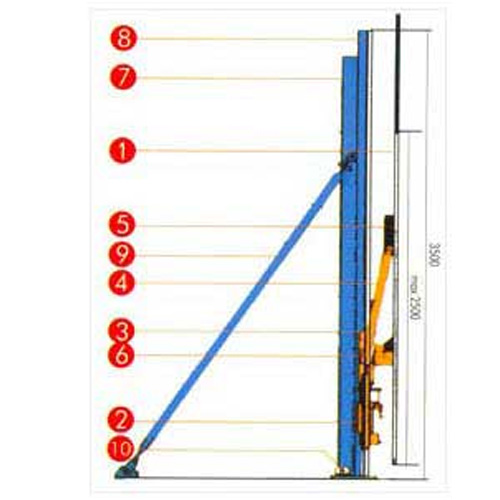

Description :

A tank jacking unit illustrated in the adjacent figure,

consist of:

Technical Data :

Kindly furnish following details to decide number of jacking sets and capacity of the Powerpack required.

Different Range of Hydraulic Jacks :

We offer hydraulic jacks manufactured under strict quality supervision. These hydraulic jacks and industrial hydraulic jacks find usage in critical application across Hydro Power Plants, Thermal Power Plants, Defence, Aerospace-Industries, Railways, etc. These jack can be custom configured and supplied with certification as required by customers. All hydraulic jacks and industrial hydraulic jacks provided by us employ international quality parts & components, that are offer long trouble free life.

Specifications :

| Usage/Application | Industrial |

| Material | MS |

| Operating Mode | Automatic |

| Voltage | 415 V |

| Power Source | Electric |

| Frequency | 50/60 Hz |

BELL HYDROMATICS manufactures Tank Jacking System with the different type of Capacity 12 MT /18 MT /25 MT

Specifications :

| Minimum Order Quantity | 15 UNIT |

| Material | Alloy Steel |

| Usage/Application | Industrial |

| Operating Mode | Automatic |

| Brand | Bell |

| Power Source | Hydraulic |

| Surface Finish | Galvanized Steel |

We offer Tank Construction System manufactured under strict quality supervision.

Specifications :

| Built Type | Panel Build |

| Usage/Application | Industrial |

| Material | Steel |

| Voltage | 220 V |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Country of Origin | Made in India |

We offer 12 MT Hydraulic Tank Jack manufactured under strict quality supervision.

Specifications :

| Minimum Order Quantity | 30 Piece |

| Usage/Application | Industrial |

| Material | MS |

| Capacity | 12 TON |

| Effective Lifting Height | 3 mtr |

| Max Working Pressure | 160 bar |

We offer Hydraulic Power Pack for Jack manufactured under strict quality supervision.

Specifications :

| Usage/Application | Industrial |

| Voltage | 110V |

| Material | MS |

| Brand | Bell Hydromatics |

| Automation Grade | Automatic |

| Phase | 3 |

Available in both standard and customized construction choices, 50 HP Hydraulic Power Pack options provide for stable performance support even in demanding working conditions. Further, these can be offered in options of hydraulic power packs or electric hydraulic packs and feature compact construction design standards. Some of its features include availability with optimum pipe fitting support, available in different working capacities, provide for economical functioning support, providing quieter operations, available with support of oil level gauge and usage suitability in industry sectors like foundries, presses, machine tools and others.

Specifications :

| Power Source | Electric |

| Usage/Application | Industrial |

| Voltage | 110V |

| Material | MS |

| Brand | Bell Hydromatics |

| Automation Grade | Automatic |

Finding its use in erection of circular structures like reactor shields, repairing of tank foundation, replacing tank bottom plate and other processes, these Jack for Storage Tank can be offered by us in different lifting capacities as per the specific end usage requirements of the customers.Available in sturdy construction support and tested lifting capabilities, these jacks can be offered with lifting capacities of 8 tons, 12 tons, 25 tons and others. Further, these are suitable for use on cryogenic tanks, gas tanks and other tank types with small or large diameters. Some end applications these are used for include enhancing volume capacity of tanks, in repairing of tank bottom plates, for repairing tank foundations and others.

Specifications :

| Usage/Application | Industrial |

| Brand | Bell Hydromatics |

| Material | MS |

| Operating Mode | Automatic |

| Max Working Pressure | 650 bar |

| Finish | Paint Coated |