Basically jack climb up on the jack rod (Part of the lifting trestle) with the required pressure to lift up the load. Its action is similar to monkey that climbs a trunk tree; i.e, first it holds up on to the trunk with its legs and lunges upwards, then it holds on to the trunk with its hands and lifts its legs up. At any time, either its hands or legs have a grip on the trunk that prevents it from falling down.

Similarly, the air hydraulic jack, air hydraulic bottle jack and jack is provided with two pairs of jaws, a lower pair of jaws and an upper pair of jaws for a perfect grip. During lifting, both the pairs are "locked". In this position the jack is only allowed to move upwards. During lifting, the lower pair of jaws grip the trestle rod while the jack lifts up. After completing the full stroke, the upper pair of jaws grip the trestle rod while the base of the jack moves upward. During the process of lowering, any one of the pairs is always locked.

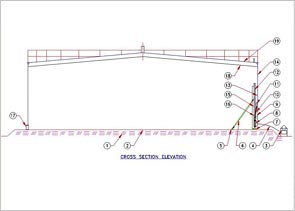

Shell To Bottom Plates Welding Is Completed.

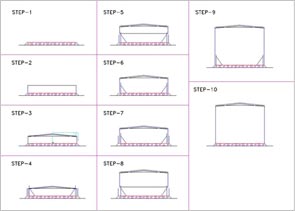

The following description gives a brief outline of working procedure of air hydraulic jack and air hydraulic bottle jack. However, modifications can be certainly made if required. (Refer the drawing below to develop better understanding).

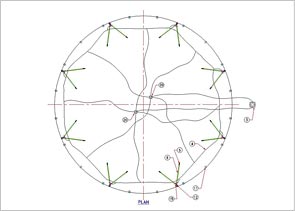

Number of trestles required for the tank depends on various factors such as :